Pneumatic Actuators + Pneumatically Operated (Actuated) Valves

We are Manufacturer, Supplier, Exporter of Pneumatic Actuators, Pneumatic Actuator Accessories, Double Acting Actuators, Pneumatic Actuated Butterfly Valves, Pneumatic Butterfly Valves, VT Series Pneumatic Actuator. Our set up is situated in Pune, Maharashtra, India and we provide our products and services to ALL OVER THE WORLD.

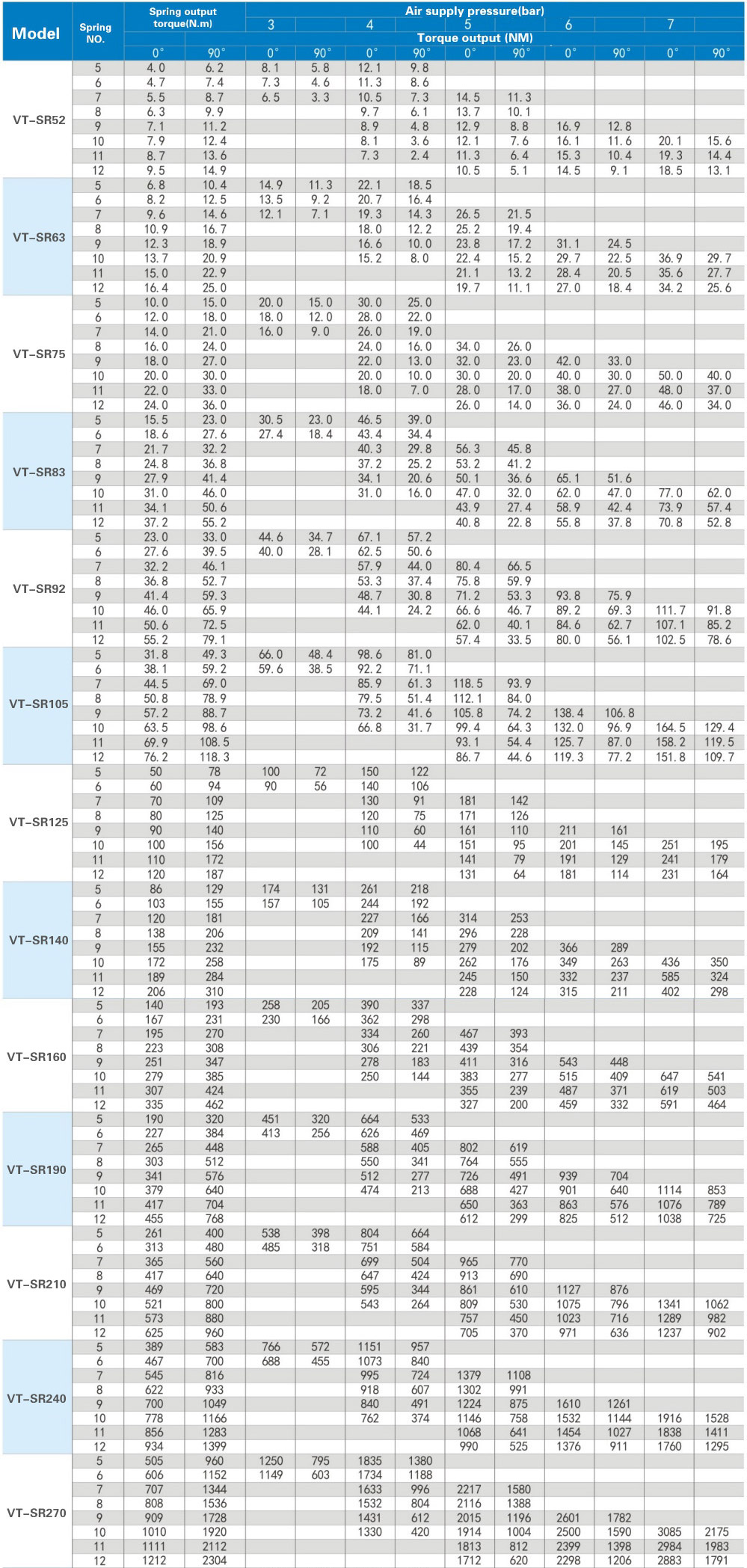

Range 4NM - 4000NM

Range 4NM - 4000NM

FEATURE

- DIFFERENT CYLINDER MODELS

- RACK AND PINION STRUCTURE

- ONE PIECE DESIGN, DOUBLE — ACTING / SINGLE ACTING

- SPRING RETURN TYPE COMMON CYLINDER END CAPS

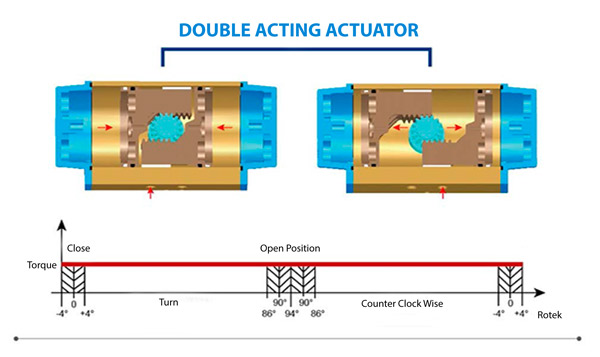

- NAMUR INTERFACE FOR EASY SOLENOID VALVE INTSALLATION

- CYLINDER ISO5211 STANDARD FOR EASY VALVE INSTALLATION

- HARDENDED CYLINDER, SPRAY END CAP, STAINLESS STEEL FASTNERS,

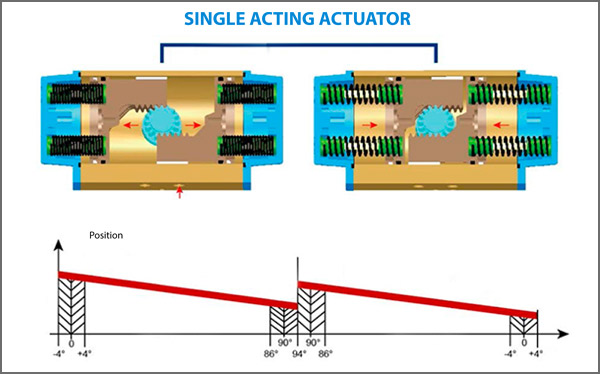

- DUAL STROKE ADJUSTMENT FOR +/- 4 DEGRESS AT BOTH ENDS

- SAFE AND CORROSION RESISTANT.

- ALL SLIDING PARTS ARE MADE OF PLASTIC BEARING, BUSHINGS,

GUIDED TO MAINTAIN MINIMUM FRICTION AND

EFFECTIVELY REDUCE GRINDING

DA 240 Double Acting Actuator Torque 2321Nm @ 5 Bar

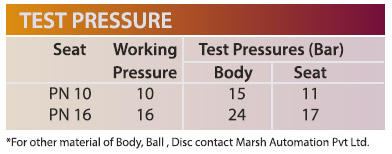

DOUBLE ACTING ACTUATOR

OPERATING SPECIFCATION

- PRESSURE RANGE 3 BARTO 7 BAR

- OPERATING TEMPERTURE -20 ° TO + 80 ° CENTIGRADE

- LOW TEMP APPLICATION -40 ° TO + 80 ° CENTIGRADE (HNBR)

- HIGH TEMP APPLICATION — 20 ° CENTIGRADE TO + 150 ° CENTIGRADE (VITON)

- HIGH TEMP AND LOW TEMP REQUIRE SPECIAL GREASE

- OPERATING MEDIUM: DRY OR LUBRICATED AIR

- STROKE ADJUSTMENT: STANDARD STRUCTURE 90 ° ROTATION +/- 4 ° ADJUSTMENT RANGE AT BOTH ENDS

- THERE IS NO NEED TO ADD ADDITIONAL LUBRICATION PARTS DURING LUBRICATION WORK, AND IT HAS BEEN PROCESSED AT THE FACTORY

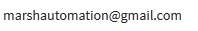

DOUBLE ACTING ACTUATOR SELECTION DATA

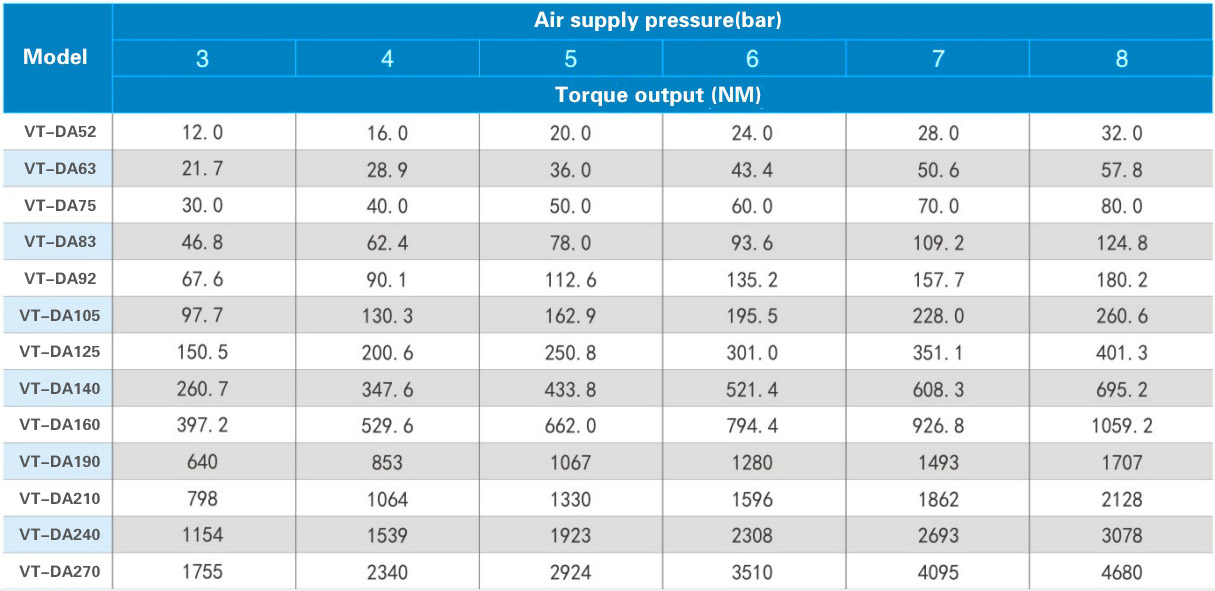

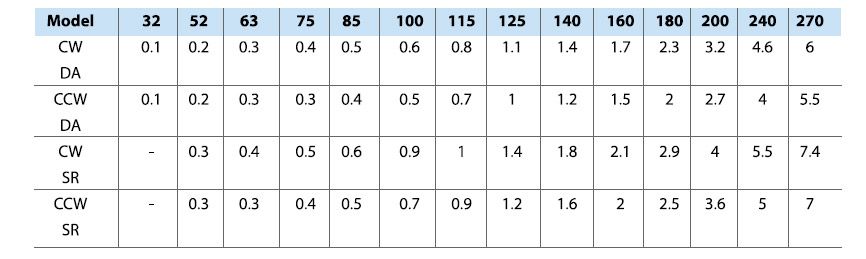

VT PNEUMATIC ACTUATOR SIZE CHART

SINGLE ACTING ACTUATOR

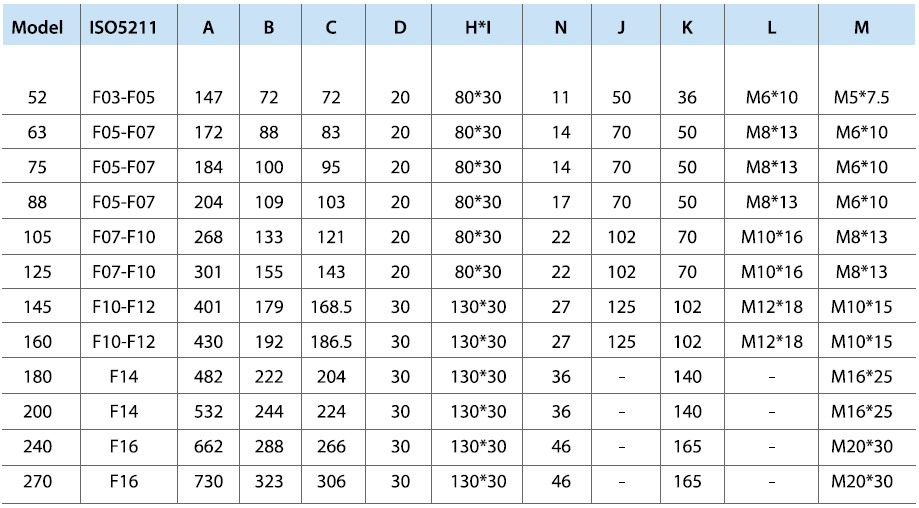

Weight Chart ( kg)

Working time ( sec)

Cycle time got without valve and should be use as aguide only.

Cycle time can be increase dramatically for actual application.

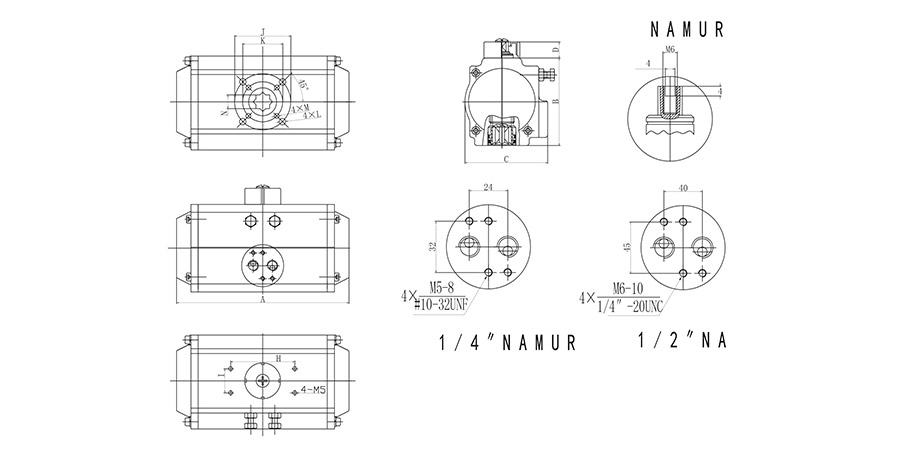

Pneumatic Actuator Operated Ball Valves

Features of Actuators

- Heavy duty Rack and pinion design

- Spring return or double acting

- Open and close adjustment stops

- True NAMUR accessory and ISO mounting

- Visual indicator, Top Mount indicator

- High temperature and corrosion resistant models available

- Solenoid, limit switches, positioner, AFR and other accessories are available

- Fully adjustable limit switches allow for fine control of on-off position

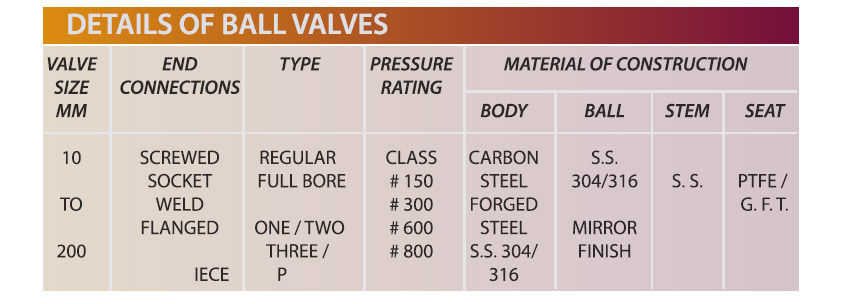

DETAILS OF BALL VALVES

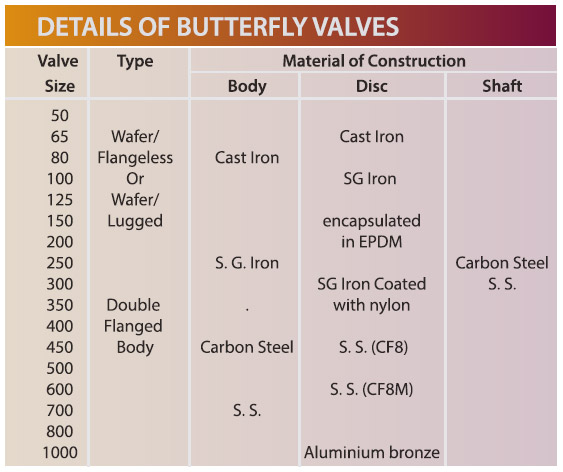

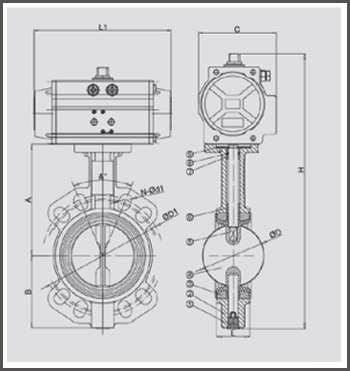

Pneumatic Actuator Operated Butterfly Valve

PNEUMATIC ACTUATOR

- Rack and pinion design

- Spring return or double acting

- Open and closed adjustment stops

- True NAMUR accessory mounting

- Visual indicator